The aluminum can: Innovation hiding in plain sight

Lessons from Coors' pioneering design that became a market standard

Hello! I’m Pat and Better by Design is my newsletter devoted to crafting quality products and excelling in the business of creativity. If you’re new here, join 1800+ product creators as we uncover new insights each week.

Only when the design fails does it draw attention to itself; when it succeeds, it's invisible. - John Berry

Intro

In the bustling mid-20th century, the Coors Brewing Company found itself in a predicament. Their old faithful, the steel can, was causing more problems than it was solving. Heavy, expensive to transport, and detrimental to the beer's quality, these cans were weighing on the business.

Outside Coors’ walls, consumers were thinking and behaving differently. People in the post-war era were more mobile than ever and needed a container to match their new lifestyle and ideals.

Faced with these twin forces, Coors leaned in and innovated. The solution was a game-changer: to make cans out of… wait for it… aluminum! This one change elevated Coors in the marketplace and quickly became the new standard.

Let’s explore why it was so significant.

Product Overview

The aluminum can is a common sight today, but its entrance onto the beverage scene was nothing short of revolutionary.

At its core, the can is… well… a can; a simple container designed to hold beverages. But that’s selling it short. The product is more complex and influential than that. It’s an object that serves the needs of both producers and consumers alike, acting as a bridge between production, transportation, sales, and consumption of beverages all around the world.

For manufacturers, the aluminum can's lighter weight compared to its predecessors —glass and steel — led to reduced transportation costs. The cylindrical shape allowed for efficient packing and shipping, while the durability of aluminum offered better protection for the product inside, reducing loss due to damage.

For consumers, it offered an unprecedented level of convenience. It was lightweight, compact, and easy to carry, making it a perfect companion for everyday activities. Its design also protected the beverage from light and air, ensuring the content's flavor remained untainted from production to consumption.

The aluminum can was more than a new container; It was a handheld encapsulation of an evolving market.

Market Context

The post-war era marked the rise of a new kind of consumerism. Economic prosperity in the US led to more leisure time, and Americans were increasingly on the move. The demand for convenience and portability was growing, and consumers sought products that could easily fit into their new lifestyles. For the beverage industry, this signaled a need to rethink the traditional heavy glass and steel containers that were less conducive to widespread, on-the-go consumption.

Beyond convenience, it was becoming evident that the existing packaging materials — glass and steel — had limitations. They were either fragile and let light in (in the case of glass) or lent a metallic taste to the beer (in the case of steel). Beverage producers needed a solution that was resilient enough to transport far and wide while maintaining their product’s quality to deliver a good customer experience.

The mid-20th century also marked a rise in environmental consciousness. People were becoming aware of the detrimental impact of industrialization on the environment. The beverage industry, like many others, was called upon to address its environmental footprint. This growing focus on sustainability made the recycling capabilities of aluminum — a highly recyclable material — an attractive feature.

During this time, the beer market was competitive. Coors, although a popular brand, was up against strong competition and the major breweries were in a constant race to gain a larger market share. The aluminum can offered Coors a way to differentiate by delivering a superior product, meeting the needs of consumers, and positioning the brand as an industry leader.

Design Levers

So Coors had both internal operational problems to solve and external customer problems to solve to protect their spot in the market.

What levers did they pull with the design to effect the change they sought?

Innovation

Coors chose to fundamentally rethink their product packaging.

This didn’t come cheap.

According to Coors the project “was the product of years of research and $10 million worth of trial and error.” Which in today’s dollars would be close to $100 million.

However, by switching from steel to aluminum, they created a product that was lighter, corrosion-resistant, and more environmentally friendly. This bold move also made subsequent innovations possible, like the 2-piece design and the pull tab.

Sometimes, you need to take a more radical approach to have a shot at leapfrogging the competition and getting ahead of evolving customer needs.

Functionality

By blocking out light and oxygen, the aluminum can provided a superior environment for beer (and other beverages), helping it better deliver upon its main purpose: preserving the beverage until the time of consumption.

Its lightweight and robust nature made it easy to transport and handle, meeting consumers' growing demand for convenience.

Aesthetics

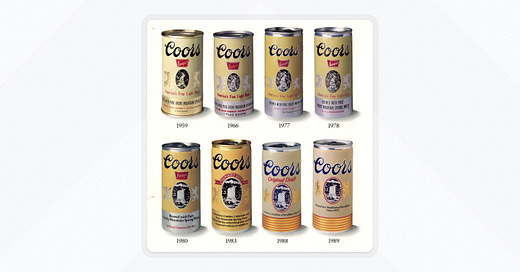

The transition to aluminum also changed the aesthetics of beverage packaging.

The smooth, curved surface of the aluminum can offered an expansive canvas for brands to express their identity. This was a marked improvement over steel, whose rougher surface could lead to subpar print results.

By using aluminum, Coors was able to introduce eye-catching designs, helping their products stand out on shelves.

Longevity

The can's robust construction ensured it withstood the rigors of long-range shipping and handling which was critical as producers looked to expand their service range. Its recyclability allowed for a longer product lifecycle, as aluminum can be recycled indefinitely with little loss of quality.

Insights for Impact

1. Incorporate lifecycle thinking

A significant factor in the aluminum can's design success was that the creators accounted for the product’s entire lifecycle.

Coors considered all stages of the product's life, from production efficiency and transport costs to consumer experience and end-of-life recyclability.

Designing with a lifecycle lens ensures a comprehensive approach that maximizes product efficiency and minimizes negative downstream impact. This thinking is even more important today as we strive for better sustainability.

2. Your operational problems can be fertile ground for innovation

Coors’ investment in aluminum resolved many of its logistical challenges while also improving the customer experience.

It’s a good reminder that identifying and improving pain points in your business operations can result in novel solutions that carry through to an improved customer experience. Particularly at the scale of an industrial beverage producer, even minor refinements can have an outsized impact.

Win-win scenarios not only exist; they create powerful compounding returns.

3. Leverage advances in materials for better performance

As Dieter Rams would say, “Innovative design moves in tandem with innovative technology.”

The technological advances to create aluminum, shape it, and decorate it opened a new world of opportunities for packaging design.

Aluminum’s properties made possible:

Lighter weight → Made it cheaper for producers to transport and easier for consumers to carry with them.

Better durability → Resulted in less breakage for producers and a better-tasting product at time of consumption for consumers.

More pliability → Supported more efficient designs for manufacturing and enabled more shapes for broader consumer choice.

Improved thermal conductivity → Allowed consumers to chill beverages faster.

4. New solutions create new problems

The original design for the aluminum can changed the industry, but it still took years of subsequent iterations to work out the kinks.

For instance:

The original can was small (only 7 ounces) because it was more feasible to develop. However, once consumer demand picked up, the pressure was back on to deliver more variety in size.

The first pull tab design for opening the can ended up causing a lot of litter as consumers discarded the fully detachable tabs. Eventually, the stay-on-tab we’re now accustomed to was invented to solve this new problem.

Product creators should view their creations as living, evolving entities that can and should be improved over time. There will always be more problems to solve. But don’t let that hold you back from shipping a meaningful update, learning, and improving.

Final Thoughts

The aluminum can serves as a reminder of the transformative potential that lies in rethinking even the most commonplace of products.

Coors turned its challenges into an opportunity, rewrote the rules of the beverage industry and, in the process, offered us a masterclass in aligning company and customer needs.

The aluminum can wasn't just a new packaging choice, it was a testament to the fact that when we listen, adapt, and innovate, a product can transform industries and change our daily lives.

If you got a little value from this post, consider subscribing, sharing, or following me on Twitter. If you got a lot of value, consider pledging to support my work with a paid subscription in the future.